Newbridge Silverware – Santa’s Workshop – Shop Now

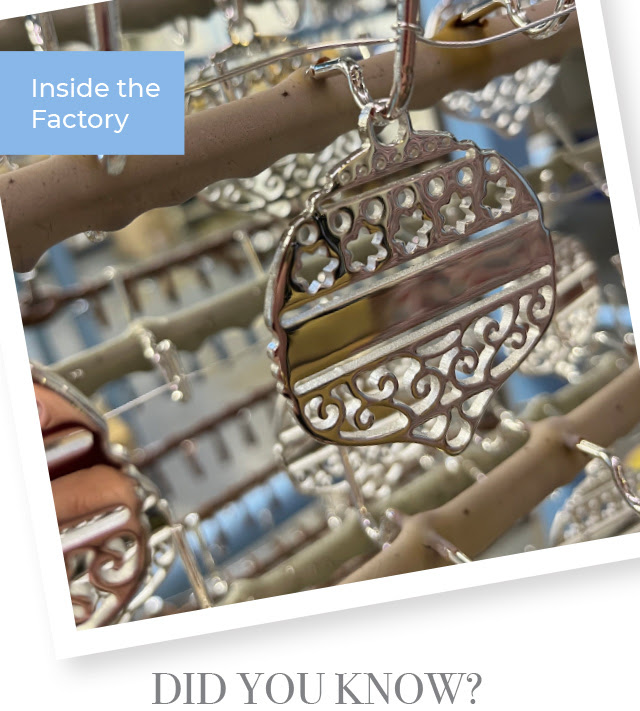

Electroplating

Newbridge Silverware has a dedicated electroplating area at the manufacturing facility. Electroplating is a chemical reaction which results in a fine layer of metal encasing another type of metal. They do this by passing electric current through a multi chemical solution along with the metal to be plated. The components to be plated are wired or hung onto a rack or jig. The components must be cleaned and free from grease or polishing compound, the plating solution has both positive and negative electrodes. The positive connection is the anode bar which has metal of the same type as the electrolyte. The components to be plated are connected to a negative bar which is called the cathode and immersed in the solution. D.C. current is applied and the metal ions are oxidised and deposited onto the components giving a fine layer of metal on the components.

This is the delicate task of securing semi precious stones and crystals to items of jewellery. Great dexterity is required by an in house craftspeople. We use a range of different stones from cubic zirconia to glass chatons to precious stones ensuring only the best quality is used to decorate Christmas decorations, giftware and jewellery. Go Shop Now.